ADSS cables. All-Dielectric Self Supporting cables. The All-Dielectric Self Supporting (ADSS) cable is a completely non-metallic structure in which the tensile load bearing elements are integral within the circular design of the cable – usually in the form of aramid yarns or stranded glass reinfroced plastic rods.

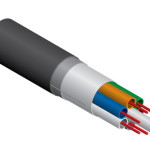

The structure of ADSS Cable

- Typically a loose tube cable design

- Designs are application specific

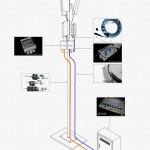

The Applications of the ADSS Cable

– Cable supports itself

- No external support or messenger wire – Uses new and existing right away

- Distribution or Transmission Lines – Designed to specific weather conditions

- NESC Light, Medium or Heavy Load

The Advantages about the ADSS Cable

- All-dielectric construction

- Eliminates bonding & grounding

- Live power line installation

- Lower costs

Key Specifications for ADSS Cable

- Maximum span distance between poles, Longer spans require more cable strength

- Installation sag: typically 1.5%. Less sag requires stronger cables

- Line voltage: Distribution: Use HDPE jacket span / Transmission: Evaluate line voltage/spacing compatibility, HDPE or track resistant jacket

- Maximum weather loading (wind, ice, safety factors, etc): Higher winds or thicker ice requires stronger cables / Can use location to determine loading per NESC.

- Fiber count: Higher counts (>72) increase the cable diameter: Larger cable diameters have more weight & carry more weather loading

- No of fibers per tube

- Maximum sag restrictions: Any clearance considerations / Restrictions may require a stronger cable

Key Information Needed for ADSS Cable Quotation

- Fiber Count

- Maximum Span Distance

- Weather Loading: NESC Light, Medium, Heavy or Other

- Line Voltage (kV) if transmission lines are used.

– System voltage worksheet required for > 69kV

– Needed to consider dry band arcing and corona resistance

Key Information Needed: Assumptions can be made if not specified

- Jacket Configuration (1 or 2): 1 likely will be assumed

- Initial Installation Sag? 1.5% is typical

Additional information to consider

- Number of Fibers per Tube: 12f/t recommended for distribution spans up to 144 fibers, 4f/t recommended > 144 fibers

- Buffer tube preference for closure routing: Polypropylene < 144, PBT > 144

- Elevation changes?

- Vertical or horizontal sag limitations/clearance

- Pollution level – important in high voltage applications

- Structure type & load capability