Photoelectric Composite Cable PoF (Power on Fiber) is a type of composite cable that integrates optical fibers and power-transmitting copper wires, capable of simultaneously providing data transmission and remote power supply for devices. In scenarios where it is not easy to obtain power at the AP end, the photoelectric composite cable can be used to remotely power the AP and transmit data, making it particularly suitable for commercial building environments. The photoelectric composite cable meets the following requirements:

- Pre-terminated photoelectric composite cables are recommended to simplify on-site installation, with dual-ended pre-fabricated photoelectric micro connectors.

- The insertion loss of the photoelectric micro connector should be ≤0.50 dB, and the return loss should be ≥50 dB; the photoelectric micro connector should withstand ≥50 plugging and unplugging cycles.

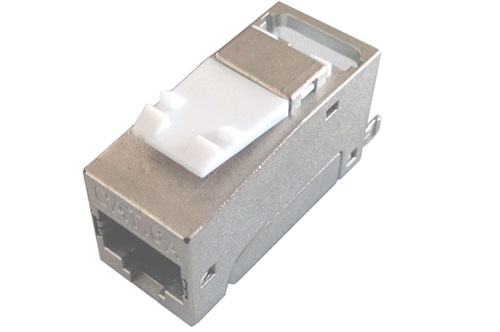

- Photoelectric Micro Connector: Integrates a pair of copper terminals and an optical fiber ferrule; the pair of copper terminals are hidden inside the connector to prevent accidental short circuits from electric shock; there must be a physical barrier between the copper terminals and the ferrule to avoid contact with the ferrule spring and prevent arcing; the deformation direction of the copper terminals must be on the same plane to avoid force bias that could cause optical abnormalities.

- The short-term tensile strength of the photoelectric composite cable should be ≥150 N,

long-term tensile strength should be ≥80 N; the tensile strength between the photoelectric connector and the cable should be ≥70 N. - The jacket uses LSZH material: Considering ease of conduit pulling, the friction coefficient should be ≤0.25.

- The copper wires are made of multiple pure copper strands twisted together, providing excellent bending performance and good flexibility for convenient installation.