Bend Radius

When installing fiber cables, tower hands should pay attention to the minimum bend radius of the fiber. Standard fiber (complies with ITU-T recommendation G.652D) can maintain a minimum bend radius of five to 15 times the fiber cable diameter. Functionally, this corresponds to about three  centimeters, or about one inch. Failure to observe the recommended bend radius can result in stress to the fiber optic core and signal loss due to light being lost into the cladding from macrobending. Bend-insensitive fiber (G.657A/B) is often selected for RRU jumpers because it is more flexible and has a much tighter minimum bend radius than standard fiber.

centimeters, or about one inch. Failure to observe the recommended bend radius can result in stress to the fiber optic core and signal loss due to light being lost into the cladding from macrobending. Bend-insensitive fiber (G.657A/B) is often selected for RRU jumpers because it is more flexible and has a much tighter minimum bend radius than standard fiber.

Tensile Strength and Support

Fiber optic cable has a tensile load rating that defines the maximum vertical rise that the cable can withstand without additional support. Cable weight is also a factor. The maximum vertical rise can be calculated using the formula:

Maximum vertical rise = (1/2 x maximum long-term tensile load)/cable weight

Using this formula, a typical jacketed 24-fiber cable can be suspended approximately 1,700 feet using a Kellems grip. However, the cable must also be secured to the tower periodically (every three to five feet) to avoid stress from the external environment (unless secured inside a monopole).

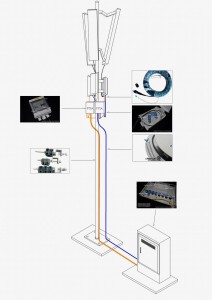

Hoisting

If a fiber cable is pre-terminated with connectors prior to hoisting, a pulling sock is used to provide the hoisting grip, transmit the tensile force to the cable, and protect the fiber connectors during transit up the tower. Multi-fiber connectors, such as the MPO (multi-fiber push on) connector, are beginning to appear in FTTA applications incorporating tower-mounted terminals. Using these connectors simplifies both the connection process and the pulling sock arrangement because only a single connector needs to be installed and protected.

Tower Clamps

Fiber optic cable manufacturers recommend clamping the fiber optic cable every three to five feet on monopole exterior, self-support and guyed towers to ensure that the cable does not move about in the wind. Stainless steel cable ties are not recommended. Rigidly anchoring the fiber optic cable to the tower subjects the cable to shear stresses both from the compression of the cable tie and the vibration of the tower structure. Instead, fiber cable hangers that isolate the fiber cable from the vibration of the tower and permit some vertical motion with temperature change are recommended.

Connector Cleaning

Fiber connectors are equipped with protective dust caps. Always leave the dust cap in place until the fiber connector is to be mated to the fiber optic transceiver in the RRU.

It is good practice to always clean the ferrule of the fiber optic connector before inserting it into the RRU. Cleaning can be accomplished using several different methods, including using pre-moistened wipes. However, a self-contained ferrule cleaning device, such as the CLETOP-S from NTT, makes cleaning on the tower top quick and easy, a benefit much appreciated by tower hands when they are suspended high in the air. The device allows the tower hand to simply plunge the ferrule into the cleaner aperture, where a controlled wiping action completes the cleaning.

Hybrid Cable

Hybrid, or composite, cable is being used more and more on towers. Hybrid cable contains both fiber and power conductors, usually ensconced in a corrugated sleeve and a polymer jacketing material. This permits hybrid cable to be mounted with standard hard line coaxial cable hangers (assuming that the hybrid cable follows the standard 7/8-inch to 1-5/8-inch coaxial feeder outer dimensions).

Hybrid cables can be arranged for single, triple or six-RRU feeds. Generally, the elements inside the hybrid construction are individually jacketed. The jacketed cables are covered by a protective corrugation, which is overlaid with a final polymer jacketing material. The over-jacket and corrugation must be removed using the incorporated ripcords prior to installation at the RRU to permit access to the interior elements.

Aside from using great care in the armor removal process, tower hands should avoid allowing the fibers to drape over the exposed edge of the cut corrugation. Over time, this can lead to fatigue and failure of the fiber optic cable elements.