On a transmission network, one cause of insertion loss on a fiber link is macro bending. This is commonly caused by tight installation or handling. As Fiber-to-the-Home (FTTH) networks lead to a significant increase of fiber installation in the last mile, the space constraints become increasingly stringent. This is driving the need for distributions hubs and network cabinets to be as small as possible while also increasing fiber density.

Additionally, fiber is being pushed into buildings and closer to the work and living spaces to carry optical bandwidth to the end user. All of these aspects have raised the significance of testing link robustness versus macro bends.

As the performance of an optical system is directly related to its wavelengths of transmission, it is mandatory to verify that no additional loss is generated by macro bends by comparing the loss characteristics at different wavelengths.

Bending loss sensitivity and Mode Field Diameter (MFD)

The single most important factor that determines the susceptibility of a fiber to macro bending induced loss is the MFD. MFD represents the area in which the light goes through and includes the core and a part of the cladding. A smaller mode field diameter indicates that light is more tightly confined to the fiber center and, therefore is less prone to leakage when the fiber is looped.

Singlemode fiber has a larger mode field diameter at 1550 nm than at 1310 nm and at 1625 nm than at 1550 nm. Larger mode fields are less sensitive to lateral offset during splicing, but they are more sensitive to losses incurred by bends during installation or in the cabling process. 1550 nm is more sensitive to bends in the fiber than 1310 nm. This is termed macro bending.

The bending effect is not a new phenomenon. When the 1550 nm wavelength was first introduced and added to the 1310 nm transmission wavelength, the bending effect was analyzed. For example, many optical fiber reports were generated comparing 1550 nm splice losses to 1310 nm splice losses in order to detect possible bending effects.

Macro Bending and OTDR Testing

OTDRs are the ideal tools for detecting and locating bends in a fiber link. As macrobend is sensitive to wavelength, most of the operators are testing fiber links with an OTDR, using two wavelengths. The historical wavelengths are 1310 nm and 1550 nm. But the best measurements to analyze macro bending should be taken between 1310 nm and 1625 nm, or between 1550 nm and 1625 nm, which are relevant wavelengths for DWDM testing.

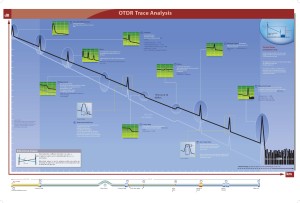

By measuring the same fiber, which includes splices and connectors, using those two wavelengths, of the following information can be provided:

– total insertion loss of the link

– total optical return loss

– loss of any event (splice, connector)

– reflectance of any event (splice, connector, etc.)

– potential macro bends

For a given event (splice or connector), if there is no macro bend, the loss measurement shall be about the same at any wavelength. If there is a large difference (>0.2 dB) between the two wavelengths, this is due to macro bend.

The most modern OTDR, such as the JDSU T-BERD®/MTS 6000, now offers this comparison automatically and as a standard with the conventional OTDR capabilities. With dedicated information it allows the technician to immediately identify (according to defined thresholds) and locate the macro bends along the fiber link.

Now that OTDR technology has moved into the 1625 nm wavelength area of the spectrum, the same analysis of bending effects must occur.

Testing Fiber Tension

Another aspect which can be tested with the OTDR is when a fiber is in tension along a long distance. In order to identify this issue, the technician must analyze the averaged attenuation of the fiber section (without any event such as splice or connector), and compare it to a mask which consists of the overall averaged attenuation with a tolerance of +/- x dB. Operators typically define this tolerance between +/-0.1 dB and +/- 0.2 dB. If this mask is reached by the OTDR trace, this indicates that there is a bend or a tension at this section. This can be performed with PC software such as JDSU OFS-100 FiberTrace™ and OFS-200 FiberCable™.

Conclusion

As fiber networks undergo increasing topology constraints, and transmission systems are expanding toward the DWDM L-Band, it becomes mandatory to make sure the installed fiber is not exhibiting abnormal bend issues. Full featured OTDRs must provide this automatic detection capability to ensure that technicians have the right tools in hand.

Source: http://www.fowiki.com/b/macrobend-detection-using-an-otdr/